- Demitasse Cups Saucers

- Brand

- Aynsley (67)

- Coalport (163)

- Dresden (59)

- Haviland (97)

- Herend (57)

- HermÈs (74)

- Lenox (101)

- Limoges (141)

- Meissen (160)

- Minton (66)

- Paragon (49)

- Richard Ginori (69)

- Rosenthal (98)

- Royal Copenhagen (75)

- Royal Crown Derby (128)

- Royal Doulton (61)

- Royal Worcester (108)

- Spode (39)

- Tiffany & Co. (64)

- Wedgwood (196)

- ... (3280)

- Material

- Bone China (487)

- Bone China, Ceramic (4)

- Ceramic (78)

- Ceramic & Porcelain (96)

- Ceramic, Porcelain (17)

- China (13)

- Clay (14)

- Earthenware (6)

- Fine Bone China (15)

- Fine China (9)

- Glass (63)

- Gold (7)

- Gold, Porcelain (5)

- Ironstone (4)

- Porcelain (1128)

- Porcelain / China (108)

- Porcelain, Gold (4)

- Pottery (9)

- Stoneware (10)

- Unknown (9)

- ... (3066)

- Style

- Aesthetic Movement (17)

- Art Deco (184)

- Art Nouveau (148)

- Asian (20)

- Baroque (19)

- Contemporary (32)

- Cup & Saucer (19)

- Decorative (33)

- Demitasse (33)

- Edwardian (22)

- Formal (13)

- French (22)

- Meissen / Dresden (12)

- Meissen Style (34)

- Mid-century Modern (121)

- Modern (14)

- Neoclassical (19)

- Rococo (16)

- Traditional (15)

- Victorian (240)

- ... (4119)

- Theme

- Type

- Coffee / Tea Set (7)

- Coffee Cup & Saucer (118)

- Coffee Pot (10)

- Cup (38)

- Cup & Saucer (884)

- Cup & Saucer Set (68)

- Cup And Saucer (28)

- Cup Saucer (10)

- Cups & Goblets (17)

- Cups & Saucers (31)

- Demitasse (41)

- Demitasse Cup (20)

- Demitasse Cup Saucer (90)

- Demitasse Set (29)

- Espresso Cup (24)

- Saucer (48)

- Tea Cup (16)

- Tea Cup & Saucer (137)

- Tea Cup & Saucer Set (10)

- Tea Set (39)

- ... (3487)

- Vintage

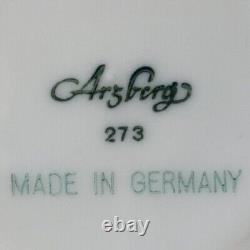

Vintage Arzberg Demitasse Expresso Set (6 Cups/Saucers) Porcelain China Germany

Arzberg Porcelain China Demitasse Set (6 Cups / 6 Saucers). In 2004, SKV-Porzellan-Union GmbH was renamed Arzberg-Porzellan GmbH.

In 2003, the company had approximately 250 employees. After 10 years Arzberg GmbH announced its insolvency. Cucina range, Daily range, Move range. Tæs/; French: "half cup"), demi-tasse, [1] or espresso cup is a small cup used to serve espresso. It may also refer to the coffee served in such a cup, though that usage had disappeared in France by the early 20th century.

A demitasse typically has a capacity of approximately 60-90 millilitres (2-3 US fl oz), half the size of a full coffee cup a tasse à café is about 120 millilitres (4 US fl oz). [2] The Italian Espresso National Institute recommends serving espresso in a white china cup holding 50?

[3] They are typically ceramic and accompanied by matching saucers, but some coffeehouses and china companies also produce brightly decorated varieties. [4][5] Another type of demitasse has a glass cup set into a metal frame, called a zarf. Demitasse cups are small because they usually serve espresso, which is a stronger, more concentrated coffee, best served in smaller portions. What makes Arzberg so special is its long tradition, its design that is instantly recognized, and its top product quality. The Arzberg brand is the incorporation of style.Timeless design and lasting quality define Arzberg! For more than eighty years famous designers have left their mark on Arzberg's renowned patterns which have been winning international awards for outstanding design over and over, and are being successfully marketed worldwide. Developing just the right shape for each pattern has always been at the center of Arzberg's attention.

Always keeping an eye on future developments and trends, Arzberg is not just expressing the style of the time but contributing a great deal to its very formation. The interaction of striking shape and practical functionality creates harmonious products you will wish to keep forever - mostly because you will instantly and profoundly feel that they are part of yourself. Sustainability, authenticity, the new interpretation of traditions and the consciousness of our own identity is important in everything we do. We are internationally inspired, but we set great value upon local production. We are open-minded, tolerant and independent from short-lived trends. Arzberg is prized the world over as a porcelain design brand. Aesthetics, functionality and durability: Arzberg. Being entwined with beauty, commitment to functionality, and relevance to life: Arzberg. What turns eating and drinking into a true experience? Form 1382, Form 2000, TRIC, Cucina. "We can no longer afford to bring products to the market which bring no joy to customers after even a short while because they are impractical, dated or simply not modern enough" - such were the words of Dr. Hermann Gretsch, whose Form 1382 revolutionised the world of porcelain in the early 30s. This legendary design, which he created back then for the time for Arzberg, has become one of the absolute classics of modern industrial design. It's on display at the Museum of Modern Art in New York as one of the few porcelain exhibits. Even today, the best designers design for life. Arzberg porcelain is always functional and always beautiful: it's created to eat from, and never have your fill. To serve food and celebrate. The power of the brand and design are lasting values.Even in a changing market. A table set for dining needs porcelain. Arzberg produces porcelain made to last. In a variety of ranges for different occasions, lifestyles and moods.

The History & Story of Arzberg. Find out more about the exciting story behind Arzberg and get to know its makers, their ideas and inventive spirit, which at the time demonstrated visionary foresight in terms of function and design. 1887 The Brits are disgruntled. The Queen is not amused: German products becoming increasingly competitive.

So Great Britain passes the "Merchandise Mark Act" which means that products from Germany must henceforth bear the description "Made in Germany" - in the hope that people will avoid them. But what is conceived as a warning very soon becomes a significant seal of quality. The Arzberg brand's own "Made in Germany" history also began around this time. "If you're such and expert on what a good terrine should look like, then go and make one, " Fritz Kreikemeier, director of the Arzberg porcelain factory, challenges the young graduate engineer Hermann Gretsch. Gretsch has criticised the fact that none of the terrines on the market allows the last remnants of food to be ladled out, never mind having an attractive shape.Gretsch goes off and designs. And the result is convincing. The term "designer" doesn't yet exist in the 60s.

But there is talk of the work being created by talented craftsmen with a particular feel for aesthetic styling. Many are striving to achieve good form. His Form 2000 is a design which - according to Löffelhardt's own artistic demands - "is such that it's worth reproducing a thousand times over". The Form 2000 becomes a bestseller. At the same time, the Museum of Modern Art in New York takes note of the design work coming out of the house of Arzberg, and includes the Form 1382, created by Löffelhardts's predecessor Gretsch, into its permanent exhibition. Arzberg is heading to become the international design brand for porcelain. There's no need to turn over the porcelain in the federal chancellery and look underneath to see who it was made by - only Arzberg is authorised to produce the crockery with its golden edging and vignette of Germany's coat of arms, the federal eagle: at the end of the sixties, the Frankish porcelain producer provided the federal chancellery with a special edition of the Heinrich Löffelhardt Form 2000. To mark Löffelhardt's100th birthday, the federal chancellery was presented with an exclusive and specially created set of tableware and some new items. There's a saying in Germany that breaking lots of pots heralds good fortune. The German porcelain industry has by now long been living on the economic miracle, and securing its international reputation over the decades by producing high quality and discerning design.With reunification and globalisation - meaning cheaper imports from Eastern Europe and Asia - the porcelain market is shattered. And then put back together again: Arzberg, as part of Hutschenreuther AG, is integrated with Winterling AG.

SKV-Porzellan-Union then acquires this design brand which is steeped in tradition. Helmut Sättler, Arzber's managing director since 1997, and the internationally renowned designer Peter Schmidt, later acquire the shares in Arzberg-Porzellan GmbH. Eat at Kolja Kleeberg's gourmet restaurant the "Vau" in Berlin and you'll soon start counting. Because this top chef's recipe for success is "Never present more than three things on the plate". Work only with the essence - but then to perfection. And this creative gourmet makes no exception when it comes to tableware: he serves his food on award-winning Form 2006 porcelain by international top designers Peter Schmidt. Such creativity sees Arzberg rediscover the value of the essence. A clear course for the future. Most creatives prefer not to burden themselves with excessive decoration. They seek authentic beauty - both in their work and in their own life.So it's hardly surprising that many designers, architects and photographers so often serve their food on Arzberg porcelain. In their circles, Arzberg forms a kind of cult: "Because the brand stands for the interplay between interesting design and functionality, which as a consumer you wouldn't want to do without - and not least because it's something you can identify with" as head designer Heike Philipp puts it. It's about history, design and quality.

Porcelain is not simply an everyday item for the dinner table - it's an expression of style, indulgence and joy in setting a table. Arzberg is the brand in porcelain design. Not all porcelain is the same.

And quality comes above all from know-how, craftsmanship and love of the product. Despite state-of-the-art technology, porcelain production is still a complex and time-consuming process. Porcelain production one of the most exciting and varied production processes. And it's our passion.100 per cent "Made in Germany". Every hand involved in its production, every hand that uses it, gives it an individual touch. You may not notice it at first sight, you might not feel it at the first touch - and yet: people take note of good porcelain by how it's been handled. "It takes a hundred hands to produce porcelain" - so say the "porcelain creators".

These are the people who design, produce and sell porcelain. And many of whose families have worked for generations in the porcelain sector.

Arzberg porcelain makers create products by applying a high degree of artisan expertise - products which have successfully served the market over many years, and others which have become classics. But this can only happen with a design that is "so good it's worth reproducing a thousand times over" as Heinrich Löffelhardt said back in the sixties. Today, the people at Arzberg craft many such designs which are worth duplicating - applying their own sensitive empathy towards materials and design to create different lines. The "Made in Germany" label has become far more than a technical seal of approval: today, it describes not just the high technological standard of manufacture, it stands equally for authenticity and genuineness - at every stage of the process. The best technology is worth nothing if no one understands the craftsmanship.

It's particularly true when manufacturing high quality porcelain which involves many small, and not so small, steps. Because in spite of all the modernisation and automation, a large part of the process is still completed by hand. And that's about to change: every step in production - the design, drying, bisque firing, glazing, gloss firing, decorating and decorating firing - all demand specialist artisan and technical expertise. Porcelain production is one of the industrial manufacturing processes with the highest levels of vertical integration! A brief insight into the production area where a lid for a Form 1382 pot is being made highlights this perfectly: place the mould on the potter's wheel, fill with liquid mass, form the cast, pour out the plaster moulds, dry the casts, lift off the cast cover, cut out the hole in the lid, open the plaster mould, take out the cast, place it on one side, put the casting mould together for the next casting, transfer the cast lid on a trolley to the drying room, work on it further in the cleaning room the next day: this is where the seams and sharp edges of the hole in the lid are scraped away using a knife and the lines cut out, cut off and contoured according to the specification, then the lid is wiped with a damp sponge and all traces of seams and processing smoothed out by hand, and then it's time for drying, baking, glazing, decorating - with the necessary part-processes and steps in-between, and - depending on the level of finish - up to six quality controls!Which means we are able to manufacture 20,000 plates and 20,000 pots every day - more than ten million a year - all checked by hand! And as an international design brand, we set the benchmark in porcelain design. Well-known designers and fresh new talent create Arzberg designs and collections - which time and again are honoured with the most prestigious design awards. In production, we generally use only lead-and cadmium-free raw materials.

Decorated items are all tested and meet all known limit standards: Certificate of Conformity. These production facilities are world leaders in the porcelain industry and, thanks to future-focused investments, manufacture products sustainably and resource-efficiently.

Rosenthal GmbH has become one of the first companies in the fine ceramics industry to be TÜV-SÜD-certified, thanks to the successful implementation of an energy management system in accordance with ISO 50001:2011 at its sites in Selb and Speicherersdorf. Below is an overview of the certifications of Rosenthal GmbH. ISO 9001:2015 Certificate Quality Management System. ISO 14001:2015 Certificate Environmental Management System. Rules on Management politics (actual German only).

Certificate Social Responsibility Management System. Ethics and Sustainability (actual German only). Code of Conduct (actual German only). I always wanted to keep in mind that we should never neglect the aesthetics in design., that even a coffee pot can be viewed like a sculpture from every angle. (Heinrich Löffelhardt designed the Form 2000 in 1954). Reduction instead of decoration: this clear commitment has moulded the Arzberg design brand's success story since 1931. Yet functional design alone is not enough to win the hearts of increasing numbers of consumers over the decades. So what accounts for our success?

It's because our designs form the bridge between function and emotion: because people love using our porcelain, because people love touching it, and because people love simply having it. The task facing our designers is quite clear, yet unbelievably complex: To translate the democratic notion of practical design into design for life, adding a personal signature. It's something only few designers achieve. The best among them are working - and working for us.

Their designs are clean and simple, timeless yet always contemporary. Hermann Gretsch made his intention clear when he said "Get to the heart of things" and then created the Form 1382. Arzberg places design at the centre. While monitoring future developments and trends, the style of each era is incorporated rather than adapted.

The result is timeless lines which all Arzberg designers follow with consistency. And inject with life - as designer Heike Philipp (designer of the Profi, Gourmet and My first Arzberg) puts it: The interplay between interesting design and function must result in harmonious products which the end user wouldn't want to be without - not least because they identify themselves through these products. Which all means high expectations in terms of usefulness, quality, design, aesthetics and relevance to life. And these are precisely the qualities that turn porcelain into "outstanding" porcelain. And as our numerous awards testify, it's what Arzberg delivers. Good design demands it: the company collected its first international awards - the Gold Medal at the VIth Triennale in Milan and at the World Exhibition in Paris - in 1936 und 1937 with Hermann Gretsch's Form 1382. Today, our design skills continue to win prizes: over the past years Peter Schmidt's Form 2006 and Heike Philipp's Gourmet alone were crowned with a total of seven of some of the most coveted international awards. Arzberg - writing design history. 1936 FORM 1382 Gold Medal VIth Triennale Milan. 1937 FORM 1382 Gold Medal World Exhibition Paris.1954 FORM 2000 Gold Medal Xth Triennale Milan. 1995 CULT iF seal Industrieforum Design Hanover.

1995 CULT "Red Dot" Design Zentrum Nordrhein Westfalen. 1998 TRIC "Red Dot" Design Zentrum Nordrhein Westfalen. 2001 CUCINA "Red dot" Design Zentrum Nordrhein Westfalen. 2002 MOVE "Red dot" Design Zentrum Nordrhein Westfalen.

2004 PROFI Good Design Award Chicago Athenaeum, Museum of Architecture and Design. 2005 PROFI iF Seal Industrieforum Design Hanover. 2006 FORM 2006 iF Seal Industrieforum Design Hanover. 2007 FORM 2006 Design Plus Ambiente 2007. 2007 FORM 2006 "Red dot" Design Zentrum Nordrhein Westfalen.2007 FORM 2006 Good Design Award Chicago Athenaeum, Museum of Architecture and Design. 2008 GOURMET Good Design Award, Japan. 2009 GOURMET iF Product Design Award 2009, Internationales Forum Design, Hanover.

2009 GOURMET Design Plus Ambiente 2009, Initiative "Form und Leben" from Messe Frankfurt, the Rat für Formgebung and the DIHT. 2011 GOURMET/Milchkrug Interior Innovation Award.

And the many well-known designers and artists who today create designs and collections for Arzberg lack nothing of their high design demands coupled with an unmistakeable perception of the demands of their time. Each adding their own personal signature, plus an appreciation of complete perfection and aesthetics. FORMING THE ZEITGEIST - WITH PROFI AND GOURMET. 2009 GOURMET Design Plus Ambiente 2009, Initiative "Form und Leben" from Messe Frankfurt, Rat für Formgebung and the DIHT. Heike Philipp breathes full life into her design.

Professionally, her creative demand is for the functional and practical. And she's passionate about adding her own interpretation. For me, it's really important that a product can withstand the demands of everyday use. So it's a bit of a tightrope walk to design functional yet emotional products with a personal touch.

The interplay between interesting design and function must result in harmonious products which the end user wouldn't want to be without - not least because they can identify themselves through these products. Born in 1969, Heike is a graduate designer, university lecturer and trained porcelain painter/décor designer. She has been head of Arzberg product development since 2006 and designed the forms PROFI and GOURMET.

RELEASING THE ESSENCE - WITH FORM 2006. 2006 Form 2006 iF Seal Industrieforum Design Hanover. 2007 Form 2006 design plus Ambiente 2007. 2007 Form 2006 "Red dot" Design Zentrum Nordrhein Westfalen.

2007 Form 2006 Good Design Award Chicago Athenaeum, Museum of Architecture and Design. Professor Peter Schmidt removes the ballast of ambiguity. He varies circles with squares in clear, honest designs.

Artistic reduction down to the true meaning. Relevant to life and simple. The function serves the design: the meaning of objects comes into the foreground. Rediscover the value of the essence.

This internationally renowned designer was born in 1937 and is the founder of Peter Schmidt Studios. As well as product design, Schmidt has also made a name for himself as a stage designer and culturist. In 2006, he designed the Form 2006 for Arzberg.

CREATING LUST FOR LIFE - WITH DAILY, CUCINA AND MOVE. Hans-Wilhelm Seitz realises the democratic notion of functional designs. His shapes seem part of the natural order of the day. A well designed shape should have an impact through its naturalness, be understood in its clarity and its simplicity and be as familiar as a good friend. My goal is not porcelain design for display in a glass display cabinet, but something for everyday use in the home.

Hans-Wilhelm Seitz was born in 1945 and trained as a ceramics modeller and mould designer. As an independent porcelain designer, he has been creating designs for Arzberg since 1975 and designed the forms CUCINA and MOVE.

UNITING THE DISPARATE - WITH TRIC. Michael Sieger seeks the whole of life in individual, everyday moments. His designs bring together items used in isolation to form a practical whole.

United through colour and form. Something unique for special occasions. Michael Sieger was born in 1968. As an industrial designer, he is the creative director of Sieger Design Consulting GmbH. He designed the Form TRIC for Arzberg and has been awarded a number of international prizes for his work. SLOWING DOWN TIME - WITH TEAWORLD. 1985 TEAWORLD TUNIS Haus Industrieform Essen.1985 TEAWORLD TUNIS Die gute Industrieform. Ulrike Bögel seeks peace in design. She moves without haste, transporting herself via the design into people's perceptions. Japanese tea philosophy was the starting point for the Teaworld design.

Peace emanates from the smooth body of the pot - something many people are hoping to find in life's everyday objects. Born in 1954, Ulrike is a graduate designer and owns her own design studio. She has worked as an independent designer with Arzberg since 1980. FORMING VALUES - WITH FORM 2000. 1954 Form 2000 Gold Medal Xth Triennale Milan.Heinrich Löffelhardt believed in the universal value of aesthetically good design. To keep on remembering that we must never neglect the aesthetics of design. , that even a coffee pot can be viewed like a sculpture from every angle. To create a range, a design must first be there which is so good, it's worth duplicating. After training as a modeller, Löffelhardt, born in 1901, worked as a freelance sculptor.

He was appointed as artistic director at Arzberg in 1952. He created the Form 2000 in 1954 in his "Werkstatt für industrielle Formgebung". GETTING TO THE HEART OF THE MATTER-WITH FORM 1382. 1936 Form 1382 Gold Medal VIth Triennale Milan. 1937 Form 1382 Gold Medal World Exhibition Paris. Hermann Gretsch created "good design for every day" for Arzberg. Its life force endures even today. We must demand that even crockery, coffee and tea pots are genuine, clean and essential in every detail."We can no longer afford to bring products to the market which bring no joy to customers after even a short while because they are impractical, dated or simply not modern enough". Designing means finding the right form to meet life's real needs. Hermann Gretsch was born in 1895.

He studied architecture, passed his trade examinations and worked as a technical teacher and buildings inspector. During his time as artistic director with Arzberg, he designed the Form 1382.